PRE- SHIPMENT INSPECTIONS

in today’s industry, success means the ability to offer the right products at the right time for a competitive price. To meet market demand, industrial manufacturers select their materials and suppliers from all over the world. With increasing globalisation, the risk of products and materials not being delivered on time and/or lacking in the quality agreed upon also grows. Clients in different parts of the world have the common need for a guarantee that ordered components, materials and equipment align with contractual specifications.

GFC Inspection Services are designed to protect the interests of buyers in their international purchasing programmes. We work with importers, wholesalers, retailers, start-ups, brands and purchasing offices from all over the world to improve the safety and quality of products and supply chain. Based on your requirements and specifications, we develop tailor-made solutions and service plans. For each individual quality control service, we develop a specific work instruction that corresponds to the product and your requirements.

SERVICES

• Verification of raw or semi-manufactured materials

• Sampling and analysis

• Staged production inspection

• Quantity determination

• Labelling and documentation control

• In-house test witnessing

• Finished product inspection

• Packing and marking inspection

• Supervision of container/truck loading

• Photographic reports

• Certification of quality, quantity & condition

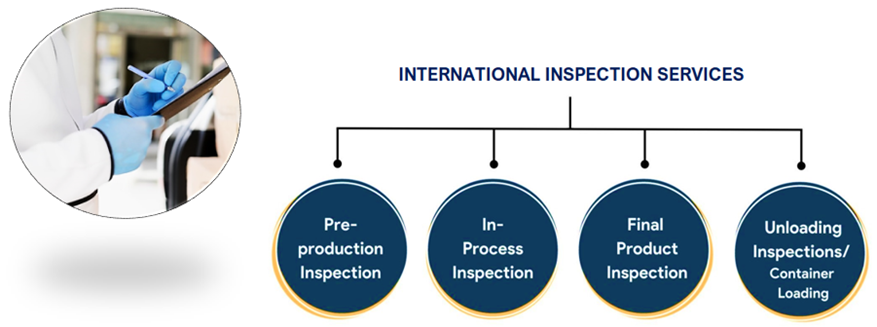

Pre-production Inspection

Pre-production inspection is a critical step in the manufacturing process. This process involves verifying the quality and readiness of materials, components, and the manufacturing setup to ensure that everything meets the specified requirements. The successful outcome of the production fundamentally relies on the vendor’s understanding of your needs and capability to meet them effectively.

In-process Inspection

In-process inspection is a vital component of manufacturing that involves the systematic examination of products during their production to ensure they meet predetermined quality standards. This proactive approach is integral to maintaining product integrity and efficiency in production lines. Identifying defects and non-compliance early, significantly reduces the cost and time involved in rework.

Final Product Inspection

This is a crucial phase in ensuring that produced goods meet all specified quality standards and regulatory requirements. It involves meticulous examination of products to confirm their compliance with design specifications and safety regulations. In the realm of third-party surveillance, final product inspections are performed by independent laboratories to provide unbiased transparent results.

Container/Truck Loading Inspection

Once goods pass the pre-shipment process, on-site inspectors ensure the correct number of different styles, sizes and quantities are properly loaded. They also check the packaging to ensure it complies with safety standards for the destination market. It is essential that goods are compliantly packed and correctly loaded to maximise safety while minimising the risk of damage during transit.

TOP 10 BENEFITS OF IMPLEMENTING PRE-SHIPMENT INSPECTIONS:

1. Ensuring Product Quality

2. Reducing Returns and Customer Complaints

3. Enhancing Customer Satisfaction

4. Compliance with Standards

5. Cost Savings

6. Streamlining Supply Chain Operations

7. Building Customer Trust

8. Risk Mitigation

9. Competitive Advantage

10. Continuous Improvement

“When GFC takes charge, problems are solved, no matter how small or large”